Gear cutting machines

Machinelist: Gear cutting machines

Gear Hobbing Machine - Vertical

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23059 · Gear Hobbing Machine - Vertical

WMW-MODUL - ZFWZ 250/5 - - 1982 -

Technical details

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-693110 · Gear Hobbing Machine - Vertical

LORENZ - F 400 - - 1977 -

Technical details

- Emuk Maschinenhandel GmbH

- Siemensstrasse 24

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 943161

-

info@emuk.info

www.emuk.info

#2070-24084 · Gear Hobbing Machine - Vertical

PFAUTER - P 400 - - 1971 -

Technical details

Machine suitable for the production of Straight spur gears, helical gears, worm gears. Equipment: Complete set of change gears, milling arbors, clamping material, manuals.

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-688537 · Gear Hobbing Machine - Vertical

PFAUTER - P 900 - - 1970 -

Technical details

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-597315 · Gear Hobbing Machine - Vertical

PFAUTER - P 1800 - - 1966 -

Technical details

- Isabelle Knops

- Opladener Str. 126

- 40789 Monheim am Rhein

- Deutschland

-

+49 (0)2173-4999611

+49 (0)2173-8546560 -

isabelle.knops@isabelleknops.com

www.isabelleknops.com

#2013-E0448 · Gear Hobbing Machine - Vertical

SAMPUTENSILI - WF 350 (HURTH MODUL) - - 12/2001 -

Technical details

Gear Hobbing Machine - Vertical / Brand: SAMPUTENSILI (Hurth Modul) Type: WF 350 / Year of construction: 2001 The machine can be inspected by appointment under working condition. Condition: Functional / ready for use. New electrical cabinet cooling in February 2024. General information on the high-performance compact machine: Universal use: - Gear hobbing Straight and helical gears Crowned conical toothing Worm gear wheels Multiple toothing Special profiles - Skive hobbing - Mould milling - HSS or carbide milling cutter - Wet or dry processing - Small, medium and large-scale production - Backlash-free twin-screw drive up to 120 rpm TECHNICAL DATA: Workpiece data: - Durchmesser max.: 400 mm - Module max.: 8 mm - Module min.: 3 mm Workspace - Workpiece: Workpiece table: - Diameter: 250 mm - Bore diameter: 150 mm - Depth: 270 mm - Feed rate radial: 40/270 mm - Feed rate axial: 200 - 600 mm Workspace - Tools: - Milling cutter diameter max.: 130/175 mm - Milling cutter length max.: 300 mm - Tangential path: 240 mm - Swivelling angle: +/- 45 degree Motorised milling head: - Spindle power: 14 kW * Backlash-free transmission of the rotary motion from the motor spindle to the milling spindle * Infinitely variable speed control within the ranges * Cutter arbour clamping device (clamping: mechanical, releasing: hydraulic) * Tangential slide guide: hydraulically clamped * Milling head swivelling on roller bearings with automatic clamping * Highly dynamic control with digital interface to the CNC control system * Interference immunity, high synchronisation quality Speeds, feeds, rapid traverses: - Milling speeds: 225 - 1.800 rpm - Workpiece speeds: 0,1 – 30 rpm Feed, rapid traverse: - radial: 0,1 – 5.000 mm/min - axial: 0,1 – 5.000 mm/min - tangential: 0,1 – 2.500 mm/min Electrics, control system: - Milling cutter drive: 18,5 kW - Total power requirement: 55 kVA - CNC path control (5-axis and milling spindle): Sinumerik 840C Machine dimensions: - Length x Width: 3.150 x 2.500 mm - Height: 2.750 mm - Weight net max.: 11.000 - 13.000 kg EQUIPMENT: - CNC path control (5-axis and milling spindle): Sinumerik 840C * Integrated programmable logic controller * Data exchange via interfaces * Remote diagnosis via modem - Emulsion equipment - Dry milling equipment (combination extraction system, chip deflector plates) - Oil mist cutting system for wet machining - Magnetic chip conveyor (width: 250 mm, discharge height: 1.000 mm) - Documentation There is no guarantee for correctness and completeness of the technical details and accessories. - Subject to prior sale -

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-02907 · Gear Hobbing Machine - Vertical

NILES - RF 7 - - -

Technical details

Gear Honing Machine

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-19716 · Gear Honing Machine

FAESSLER - K 400 A CNC - - 2004 - NUM 1050

Technical details

6-Axis machine with - CNC control NUM 1040 with Indramat Servo Drives - huge set of accesories - Set of Grinding tools - exhauster

Datasheet

Request / Contact

- IMZ Maschinen Vertriebs GmbH

- Marie-Curie-Straße 19

- 73529 Schwäbisch Gmünd

- Deutschland

-

0049 (0) 7171 987130

0049 (0) 7171 9871329 -

info@imz.de

www.imz.de

#1075-6811 · Gear Honing Machine

GLEASON HURTH - ZH 125 CNC E - - 2001 - SIEMENS 840 C

Technical details

with measuring and palletizing system from Hörzer & Fehrenbach for gearwheels (bore receiver) Workpiece diameter: 17-39.5 mm Component height: approx. 6-15 mm Oblique as well as straight toothed

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-309529 · Gear Honing Machine

REISHAUER - RZR - - 1996 -

Technical details

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-0337091 · Gear Honing Machine

FÄSSLER - D - 250 / H5 - - 1983 -

Technical details

Gear Ø, min./max. 10 / 250 mm Module range 1 - 5 Length of teeth / max. table stroke 500 mm Height of centres of tailstocks 220 mm Max. weight of workpiece 50 / 100 kg Honing head swivelling +/- 35 ° Speeds of honing tool 20 - 500 rpm Size of honing tool, Ø x width 300 x 40 mm Workpiece speeds 500 - 3,000 rpm Total adjustment of cross slide 270 mm Rapid traverse of cross slide 50 mm Infeed travel of cross slide, mechanical 1 - 8 mm/Ø Roughing / finishing infeed 1 - 29 / 0.2 - 2.8 mm/sec Table speeds, hydraulic 0 - 6 m/min Total electrical load 5.5 kW - 380 V - 50 Hz Weight 3,200 kg Accessories / Special Features * Working parameters can be preset using counters and control units. Automatic working process with workpiece counter. * All roughing and finishing infeeds can be adjusted by a decade switch; as well as by table reverse times and fast infeeds with preset times (1sec = Ø 0.04 mm), set on a potentiometer. Ampere display, etc. * Convex honing and conical honing are possible via templates. Asymmetric honing is also possible if the workpiece is prepared appropriately (i.e. pre-shaped). * Separate honing oil unit with magnetic separator and fine filter. * Mechanical tailstocks for manual loading. * Oil mist separator. * Sliding doors with foot switch. * Separate hydraulic unit. Condition : Good. Machine can be inspected under power. Delivery : Ex stock, as inspected. Payment : Net, after conclusion of contract. We have a large selection of gear machines available. Please let us know your requirements.

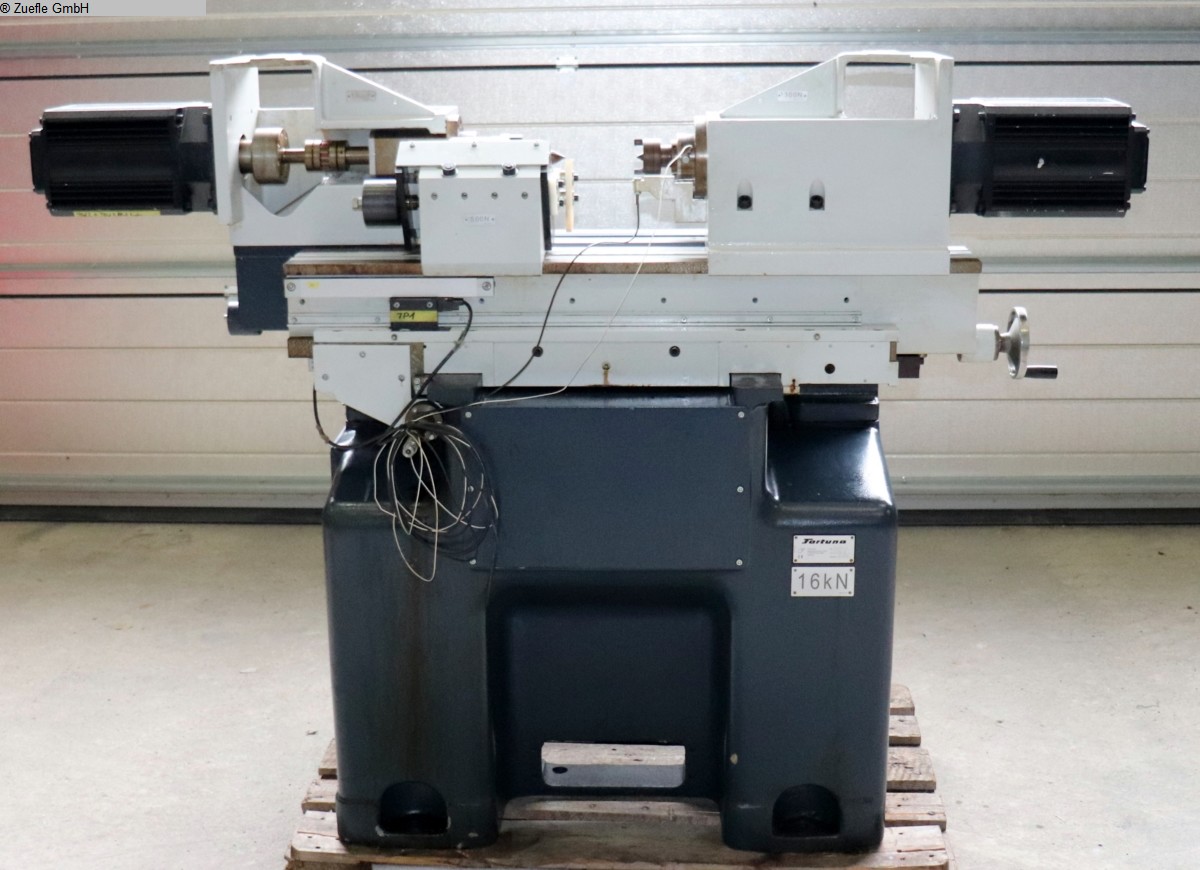

Gear Noise under Load Testing Machine

- Zuefle GmbH

- Levi-Strauss-Str. 121

- 97232 Giebelstadt

- Deutschland

-

+49 (0)9334-978608-0

+49 (0)9334-978608-2 -

info@zuefle.com

www.zuefle.com

#1139-00268 · Gear Noise under Load Testing Machine

HURTH - ZP 300 - - 2000 -

Technical details

The gear noise tester HURTH ZP 300 is used for noise tests of external gears with chance of error detection. Our machine is disassembled in our stock. The machine is in good working condition and can be overtaken now. Come and inspect the tester in Giebelstadt, nearby 80 min to Frankfurt airport. Description: This tester HURTH ZP 300 was in ´2000 complete mechanical overhauled and modernized by company FORTUNA (grinding machine specialist) with: - 2 new servo motors directly adapted to spindles, type BAUMÜLLER DS 100-S (17kW, 4000rpmn, 36Nm) - 2 new spindles of typeFORTUNA FIVY 90RL 190 HSK-40.301 for max. 6000rpm - 2 new couplings between servo and spindle of type KTR - HEIDENHAIN linear encoder for measuring of axial shift - HEIDENHAIN linear encoder LS 476 ML120mm for measuring of radial shift - 4 new BRUCKNER centers With this machine there is no controlling unit. So the machine is predestinated for customer, who wants to install new controller! Of this type we have 2 similar machines in stock.

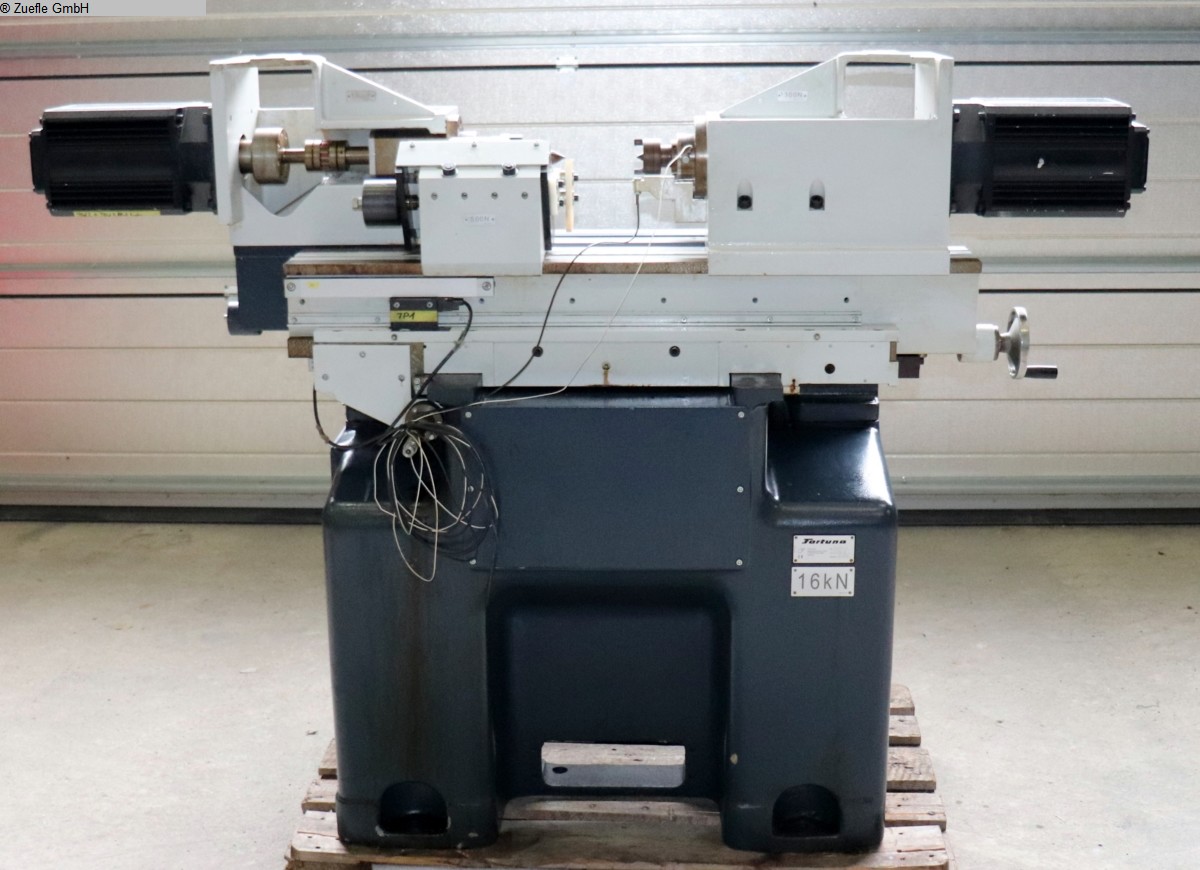

- Zuefle GmbH

- Levi-Strauss-Str. 121

- 97232 Giebelstadt

- Deutschland

-

+49 (0)9334-978608-0

+49 (0)9334-978608-2 -

info@zuefle.com

www.zuefle.com

#1139-00269 · Gear Noise under Load Testing Machine

HURTH - ZP 300 - - 2000 -

Technical details

The gear noise tester HURTH ZP 300 is used for noise tests of external gears with chance of error detection. Our machine is disassembled in our stock. The machine is in good working condition and can be overtaken now. Come and inspect the tester in Giebelstadt, nearby 80 min to Frankfurt airport. Description: This tester HURTH ZP 300 was in ´2000 complete mechanical overhauled and modernized by company FORTUNA (grinding machine specialist) with: - 2 new servo motors directly adapted to spindles, type BAUMÜLLER DS 100-S (17kW, 4000rpmn, 36Nm) - 2 new spindles of typeFORTUNA FIVY 90RL 190 HSK-40.301 for max. 6000rpm - 2 new couplings between servo and spindle of type KTR - HEIDENHAIN linear encoder for measuring of axial shift - HEIDENHAIN linear encoder LS 476 ML120mm for measuring of radial shift - 4 new BRUCKNER centers With this machine there is no controlling unit. So the machine is predestinated for customer, who wants to install new controller! Of this type we have 2 similar machines in stock.

Gear Shaper

- Brandner Revalue GmbH

- Mozartstr. 24

- 89264 Weißenhorn

- Deutschland

-

+49 (0) 7309 928 58 75

+49 (0) 7309 928 58 74 -

mb@b-rv.de

www.b-rv.de

#2011-219903 · Gear Shaper

MAAG - SH 450 - - 1974/2003 -

Technical details

- Brandner Revalue GmbH

- Mozartstr. 24

- 89264 Weißenhorn

- Deutschland

-

+49 (0) 7309 928 58 75

+49 (0) 7309 928 58 74 -

mb@b-rv.de

www.b-rv.de

#2011-219904 · Gear Shaper

MAAG - SH 250 - - 1970/2008 -

Technical details

- Brandner Revalue GmbH

- Mozartstr. 24

- 89264 Weißenhorn

- Deutschland

-

+49 (0) 7309 928 58 75

+49 (0) 7309 928 58 74 -

mb@b-rv.de

www.b-rv.de

#2011-219905 · Gear Shaper

MAAG - SH 250/300 - - - Siemens 840D

Technical details

Gear Shaping Machine

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24154 · Gear Shaping Machine

LORENZ - SN 4 - - ca 1981 -

Technical details

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23230 · Gear Shaping Machine

LORENZ - SN 4 - - ca 1981 -

Technical details

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-E23259 · Gear Shaping Machine

GLEASON- PFAUTER - P 1200 S - - 2008 - Siemens 840D Powerline

Technical details

Gleason-PFAUTER CNC gear shaping machine P 1200 S for the production of internally and externally cylindrical gears with internal and external teeth and other rolling profiles and moulds profiles and moulds that regularly occur on the cylindrical workpiece circumference and for the production of profiles in the single part process. Special version with hydraulic shaping head H1 SCOPE OF EQUIPMENT: - Basic machine P1200S, Siemens 840D Powerline (XP) - Hydraulic shaping head H1 - Signal light (3-colour) - Extended software for fault diagnosis - Telephone diagnosis system - Chip disposal through table bore - Set of adjusting wedges - Monitoring devices - Warm-up programme - Network connection (Ethernet) - 19" flat control panel OP 015A - Offline version "dialogue programming - Vapour separator make "3nine" type KLARA - Machine installation under floor - Rinsing gun - Mounting device - Cutting wheel holder ( 3 pieces ) - Cutting wheel holder for sheep cutting wheels - Cutting wheel holder for sheep cutting wheels - Special cutting wheel holder - Preparation for retrofitting paper belt filter system - Measuring device for machine P 1200 S - Clamping base body - BDE/MDE interface in the machine control cabinet Modification of vapour separator make "3nine" type Klara type EMMA Working range and technical data: Nominal workpiece diameter External toothing. . . . . . . . 1.200 mm Internal gearing. . . . . . . . 1.200 mm Largest workpiece circulation Ø without counter stand... 1.400 mm Nominal machine module approx. - with hydraulic impact head H1... 16 mm Shaping spindle stroke rate range - with hydraulic shaping head H1 max. 80 min-1 Largest toothing width - with hydraulic shaping head H1... 350 mm Smallest pitch height of the hydrostatic screw guide - with hydraulic shaping head H1... 850 mm Smallest/largest distance between tool and workpiece axis - with hydraulic shaping head H1... 0 - 750 mm Axial slide adjustment range - with hydraulic shaping head H1... 1.100 mm Lowest shaping spindle position above table with hydraulic shaping head H1 ** with upper position Shaping stroke... 560 mm Column side offset range - with hydraulic pusher head H1... +/- 50 mm Mould mounting cone - with hydraulic shaping head H1 - HSK-80(hollow shank taper according to DIN 69063) Workpiece with external gearing: - Module max. 16 mm, - max. toothing width 350 mm, - max. external Ø 1.200 mm, Workpiece with internal gearing: - Module max. 16 mm, - max. toothing width 350 mm, - max. circulation Ø 1.400 mm, - max. internal Ø 1.200 mm, - max. shaping wheel Ø 260 mm, - Mounting in shaping spindle HSK-80, - Slide travel; X/Y/Z- 750 /100 / 1.100 mm, Workpiece table: - Outer Ø 1.200 mm, - bore 300 mm, - max. load 150 kN, - Cooling unit, Küma, type OWT600-3KK, year 2008, - Hydraulic unit, manufactured by Parka, - Centrifuge, made by Steimel, - Air filter, Indusa, type EL4001NTDASECL/O, version AOO, max. air capacity 4.000 m³/h

Datasheet

Request / Contact

- Leyendecker & Hollmann GmbH

- Giesenheide 18

- 40724 Hilden

- Deutschland

-

+49 (2103) 28097-0

+49 (2103) 28097-99 -

info@LHmachine.com

www.LHmachine.com

#1083-03265 · Gear Shaping Machine

GLEASON- PFAUTER - P 1200 S - - 2008 - Sinumerik 840 D

Technical details

Workpiece with external gearing Largest modulus (in steel with approx. 600N/mm²) 16 mm - Maximum gear width 350 mm - Largest outside diameter 1. 200 mm Workpiece with internal gearing Largest modulu (in steel with approx. 600N/mm²) 16 mm - Maximum gear width 350 mm - Maximum swing diameter 1. 400 mm - Maximum inner diameter 1. 200 mm Tool - Maximum impeller diameter 260 mm - Stroke length 50 mm – 380 mm Equipment/Accessoires: Special version with hydraulic cutting head H1 workpiece diameter: External gears 1. 200 mm Internal gears 1. 200 mm Largest workpiece swing diameter - without steady rest 1. 400 mm Oil mist exhauster „3nine“ type KLARA Cutting wheel holder (3 pieces) Measuring device for machine P 1. 200 S

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24003 · Gear Shaping Machine

GLEASON-Pfauter - GP 130 S - - 2005 - Siemens 840 D

Technical details

Counterhold without center hydraulically operated counter arm and Linear guides. For automatic ring loader, with 4 stations

Datasheet

Request / Contact

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17457 · Gear Shaping Machine

LIEBHERR - LS 122 - - 2002 - SINUMERIK 840 D

Technical details

Tool: number of teeth = 1 - 200 module min. 0.05 Workpiece: number of teeth = 1 - 1500 module min. 0.05 Counter holder rotatable with 4 positions automatic workpiece changing device Linear workpiece conveyor

Datasheet

Request / Contact

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17456 · Gear Shaping Machine

LIEBHERR - LS 122 - - 2002 - SINUMERIK 840 D

Technical details

Tool: number of teeth = 1 - 200 module min. 0.05 Workpiece: number of teeth = 1 - 1500 module min. 0.05 Counter holder rotatable with 4 positions Automatic workpiece changing device Linear workpiece conveyor

Datasheet

Request / Contact

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

#1118-1554 · Gear Shaping Machine

LORENZ - LS 82 - - 1999 - SIEMENS 840 C

Technical details

equipment · stroke positioning adjustment controlled by CNC · stroke length adjustment mechanical-manually · machine is fixed to the ground with specific damping shoes (part of the delivery scope) · oil mist exhaust system · tailstock · shaping spindle and lift of shaping head equipped with hydrostatic bearing

Datasheet

Request / Contact

TOP Manufacturer:

LORENZ - PFAUTER - KLINGELNBERG - HURTH - GLEASON- PFAUTER - LIEBHERR - GLEASON - MAAG - REISHAUER - HOEFLER -